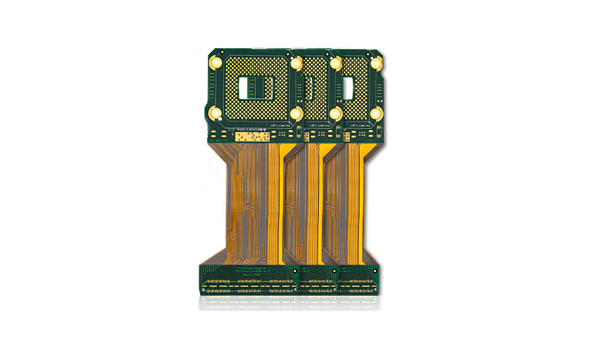

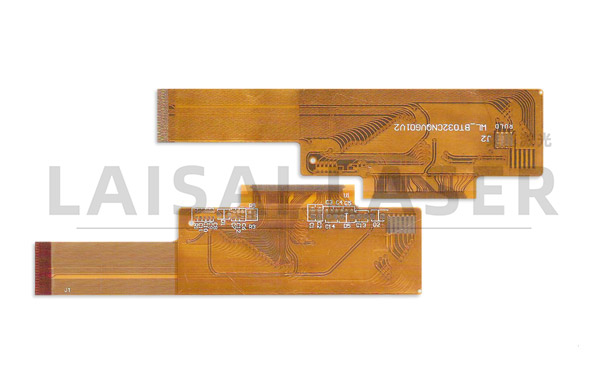

According to market feedback, laser cutting machines can currently perform precision cutting of flexible circuit boards and organic cover films without the need for special pressure and mold fixation. The ability to overuse high-energy laser sources and precisely control laser beams can effectively increase processing speeds and achieve more precise processing results. Through the combined motion of galvanometer scanning and linear motor two-dimensional platforms, the processing difficulty is not increased due to complex shapes and tortuous paths. Laser cutting is commonly used for precision molding of flexible circuit boards, hard-soft boards, and FPC film windowing.

Application of laser precision cutting in forming FPC:

1. Flexible circuit board laser processing technology is mainly used for FPC shape cutting, cover film window opening, drilling, etc. The following are the main benefits:

2. Directly used for laser cutting according to CAD data, it is more convenient and quick, and can greatly shorten the delivery cycle.

3. Do not increase the difficulty of processing due to complex shapes and curvatures.

4. When opening the cover film, the edges of the cut cover film can be neat and round, smooth, burr-free, and glue-free. The use of mold pressing machine processing to open the window will inevitably cause burrs and glue overflow after the die is punched near the window. This burr and glue overflow are difficult to remove after the pressure is applied to the pad, which directly affects the quality of the subsequent coating.

5. The processing of flexible sheet samples often changes the cover film window because the customer needs to change the line and pad position. The traditional method requires the replacement or modification of the mold. This problem can be easily solved when using laser processing, because by simply importing the modified computer-aided design data, the cover film that you want to open the window graphics can be easily and quickly processed, which will win the company market competition opportunities in terms of time and cost.

6. Precision laser cutting machine is an ideal tool for flexible circuit board forming processing. Lasers can process materials into any shape.

7. In the past mass production, mechanical stamping forming dies were used to form many parts. However, the hard stamping die process has large losses and long delivery cycles, which is impractical for part processing and forming, and the cost is very high.

FPC market analysis report:

In the early days, FPC was only used in special industries such as military and aerospace. With the development of various information terminal equipment, FPC has gradually been applied to civil and commercial fields. In recent years, the growth mode dominated by consumer electronics growth mainly includes the following aspects:

1. Personal computers: including desktop computers and laptops, as well as wearable computers under production.

2. External computers. The above two markets are the largest in global FPC demand, but the growth rate is slow.

3. Mobile phones: 6 to 10 FPCs are used in flip phones. These FPCs are mainly single-piece and double-sided. FPC is used for display modules and camera modules with multi-layer structures.

4. Audio and video equipment is the third application field of FPC: portable products (such as MP3, MP4, mobile TV, mobile DVD, etc.) and flat-panel displays will continue to increase the number of FPCs.

5. Other application markets also include medical devices, automobiles and instruments.

The future development trend of FPC mainly includes three aspects:

1. The development of TFT-LCD and PDP display technology has promoted the development of single-sided and double-sided display towards high density. The line shape is finer and the aperture is smaller. The line width of single-sided and double-sided FPC lines is 1.5mil/1.5mil, and the diameter of the small hole is 0.1~0.05mm.

2. Adopt the two-layer method of FCCL flexible copper clad laminate material with high dimensional stability. Due to the demand for mobile phones with high flexure requirements and TFT-LCD products with high dimensional stability requirements, the two-layer FCCL flexible copper clad laminate material technology is mature and cheap, and the use rate of glue-free two-layer FCCL is getting higher and higher.

3. Develop towards COF (CHIPONFLEX). Driven by the TFT-LCD and integrated circuit packaging substrate markets, COF has a good development momentum. The line spacing of single-sided COF is 10μm, while the line spacing of double-sided COF is 15μm, and the aperture of the small hole is less than 50μm.

Laser perforation in leather involves the use of a CO2 laser integrated into a laser cutting and engraving machine, commonly referred to as a laser engraving cutting machine. In reality, it is most appropriately called a laser engraving cutting machine....

Leading laser film cutting machine manufacturer, wide application industry, contact us. Professional r&d laser machine 20 years, sold well in more than 100 countries. Top manufacturer....

When you are planning to buy an acrylic laser cutting machine, you may be wondering about the price of a CO2 laser cutting machine. Depending on different specifications and configurations, the price of CO2 laser cutting machines ranges from hundreds of t...

The variety of PVC welders machines is suitable for any customers.Buy Pvc Welding Machine and more at the best deals and lowest prices online....

Laser welding machines can be said to be indispensable equipment in the welding industry, and have also received unanimous praise in application, making the equipment have considerable sales in the market. So what materials are used for such a good equipm...